Understanding the Key Elements and Repair Service Methods for Packaging Machine Maintenance

Effective upkeep of packaging machines pivots on a comprehensive understanding of their key components, including the frame, drive system, and sealing devices. Recognizing usual maintenance concerns, coupled with the execution of preventative techniques and troubleshooting strategies, can substantially enhance equipment dependability. The choice of fixing practices, consisting of the use of OEM parts and the relevance of licensed specialists, plays a critical role in lessening downtime. To truly comprehend the complexities of these systems and their upkeep, one should take into consideration the more comprehensive ramifications of disregarding these essential methods.

Secret Parts of Packaging Devices

Packaging makers are composed of numerous vital parts that collaborate to make sure reliable and reliable product packaging procedures. At the core of these equipments is the structure, which gives architectural honesty and houses the numerous operating components. The drive system, usually a mix of equipments and motors, helps with the movement of components, enabling specific procedure throughout the product packaging cycle.

One more vital element is the conveyor system, which transfers products via various phases of the packaging process. This is usually enhanced by sensing units and controls that keep track of the position and rate of products, making sure synchronization and reducing errors. The loading system is important for precisely dispensing the best amount of item into plans, whether in fluid, powder, or solid kind.

Securing mechanisms, consisting of warm sealers or glue applicators, play an important role in safeguarding bundles, stopping contamination and expanding shelf life. Additionally, classifying systems are essential for providing needed product details, making sure compliance with guidelines. The control panel, furnished with user-friendly interfaces, permits operators to take care of machine functions, display performance, and make changes as needed, making sure optimal performance and efficiency in product packaging procedures.

Typical Upkeep Concerns

Reliable procedure of product packaging makers counts heavily on regular maintenance to protect against usual issues that can disrupt manufacturing. Among these issues, mechanical wear and tear is common, particularly in elements like electric motors, conveyors, and seals, which can lead to unanticipated downtimes. Additionally, misalignment of parts can lead to ineffective operation, creating items to be inaccurately packaged or damaged during the process.

One more typical maintenance problem includes the build-up of dirt and particles, which can hinder the maker's sensing units and relocating parts. packaging machine repair service. This not only influences performance but can likewise pose safety risks. Additionally, lubrication failures can lead to boosted friction, resulting in overheating and ultimate part failing.

Electrical problems, commonly stemming from loosened links or worn-out circuitry, can disrupt machinery functions, causing substantial production hold-ups. Software program problems due to out-of-date programs or improper setups can hinder the equipment's procedure, requiring instant intervention. Resolving these common upkeep issues proactively is essential for making certain optimum performance and longevity of packaging machinery.

Preventative Maintenance Approaches

Executing preventative maintenance strategies is crucial for maintaining the efficiency and reliability of product packaging machines. These approaches encompass a systematic strategy to maintenance, concentrating on the normal evaluation and maintenance of equipment to preempt possible failures. By adhering to an arranged upkeep program, drivers can identify deterioration on elements prior to they cause significant breakdowns.

Key aspects of a preventative maintenance approach include regular examinations, lubrication, cleaning, and component substitutes based on producer suggestions. Using checklists can enhance this process, ensuring that no necessary tasks are ignored. Additionally, keeping precise documents of upkeep activities aids in tracking the device's performance in time, assisting in educated decision-making relating to future upkeep requirements.

Training team on the relevance of preventative upkeep enhances compliance and promotes a culture of positive treatment. Implementing a predictive upkeep component, utilizing data analytics and sensor innovation, can even more maximize equipment efficiency by predicting failures before they happen.

Troubleshooting Techniques

When encountered with breakdowns or ineffectiveness in packaging devices, using organized troubleshooting methods is vital for identifying and fixing problems swiftly. The first step in efficient troubleshooting is to establish a clear understanding of the maker's operational specifications and performance metrics. This entails reviewing the device's specifications, in addition to any pop over to this site mistake alerts or Get the facts codes shown.

Following, drivers ought to perform a visual examination, inspecting for evident indicators of misalignment, damage, or wear. This frequently consists of examining sensing units, belts, and equipments to determine prospective reasons for breakdown. Gathering operational data, such as manufacturing prices and downtime logs, can also supply insights into recurring concerns.

When prospective troubles are identified, making use of a rational strategy to separate the origin reason is critical. This might call for testing individual elements or systems in a controlled fashion. Participating in discussions with operators who engage with the machinery on a regular basis can generate important comments concerning uncommon behaviors or patterns.

Fixing and Substitute Ideal Practices

An extensive understanding of fixing and substitute best techniques is vital for preserving the durability and efficiency of product packaging devices. On a regular basis assessing the problem of equipment elements allows for timely intervention, stopping even more substantial issues that can cause expensive downtimes.

When repair services are needed, it is vital to use OEM (Original Tools Manufacturer) parts to ensure compatibility and performance. This not only preserves the integrity of the device however additionally upholds guarantee contracts. Furthermore, it is a good idea to keep a supply of critical extra components to promote quick substitutes and lessen functional disturbances.

For complex repairs, engaging qualified service technicians with specialized training in packaging machinery is suggested. They possess the experience to detect problems properly and implement repair work efficiently. Documenting all fixing activities and components replacements is critical for maintaining a detailed maintenance background, which can aid in future troubleshooting.

Lastly, carrying out an aggressive technique, including routine examinations and predictive upkeep methods, boosts the dependability of packaging machines. By adhering to these finest learn the facts here now methods, services can make certain optimum device efficiency, decrease functional threats, and prolong equipment lifespan.

Verdict

To conclude, a complete understanding of product packaging maker elements and reliable upkeep approaches is essential for ideal efficiency. Routine inspections and making use of OEM components can dramatically minimize downtime, while a well-documented maintenance background cultivates proactive care. Utilizing certified service technicians even more boosts repair top quality and integrity. By applying these practices, organizations can make sure the longevity and effectiveness of packaging equipments, ultimately adding to improved functional productivity and lowered prices.

Reliable maintenance of product packaging devices pivots on a thorough understanding of their key elements, consisting of the framework, drive system, and sealing systems.Efficient procedure of product packaging makers relies greatly on routine maintenance to protect against usual concerns that can interfere with production.Executing preventative maintenance strategies is crucial for sustaining the effectiveness and integrity of product packaging machines. In addition, keeping exact documents of maintenance activities aids in tracking the machine's efficiency over time, helping with educated decision-making pertaining to future maintenance requirements.

Jake Lloyd Then & Now!

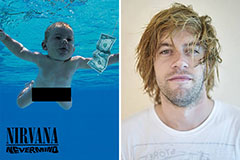

Jake Lloyd Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!